In this Q&A, Talha Khan tells us about his experience as an intern with SINDRI, the project he has been working on and how it will support his next career steps.

-

Why did you apply for this internship?

During my third year of study of my Mechanical Engineering degree at The University of Manchester, I was looking at internships and placements that I could undertake before completing my masters, to gain experience and develop my technical skills.

I selected this one-year placement with EDF R&D UK within their modelling and simulation centre as it was an opportunity for me to enhance my skills using modelling and simulation software, as well as programming and teamwork, whilst working on new interesting projects, such as this one with the SINDRI partnership.

Also, my interest in the nuclear sector motivated me to apply for this internship, to have the chance to experience working in an area I am passionate about.

-

What was the main focus of your internship?

My internship has mainly been focused on weld modelling, this ties in with the SINDRI project with the development of the Welding Workbench. This is a tool built for weld residual stress modelling, designed to make the setup, running and interpretation of finite element-based models a lot easier and quicker.

I have been involved in the validation of certain weld models, as well as the automation of the scripts that that allow the building of meshes and running of simulations, and then tying all of it together with the design and creation of the user interface.

- What were the main results and outcomes of your work?

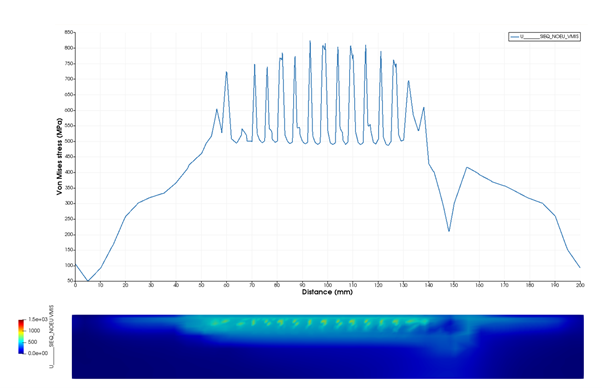

I was able to reproduce a tekken weld test using code aster with reasonably accurate results, this included building a mesh, running a heat source calibration, metallurgical computation and finally arriving at a mechanical solution of the residual stress.

Completing this process was extremely beneficial for the development of the welding workbench, as it laid the framework for it, with the workbench intended to allow people to follow the same steps in a more simplistic and automated fashion. As of now a first version of a working welding workbench has been released that allows the mesh building and thermal calibration of certain specific weld geometries.

-

How do you think this experience will support your future career plans and aspirations?

I think I have advanced my technical skills massively during this placement, with heavy use of programming (python), as well as use of other software that could be of great benefit to my career in the future.

Also, working on collaborative projects has allowed me to develop my presenting, team working and communication skills, and overall, I believe the experience gained working for EDF R&D will set me up very well for the future.