This five-year Prosperity Partnership, entitled Synergistic utilisation of INformatics and Data centRic Integrity engineering (SINDRI), will help to reduce the cost of future low-carbon energy generation as part of the drive to achieve a Net Zero carbon economy. Over the course of the research programme, the partnership will create seven new research roles, and incorporate eighteen PhD studentships.

Credit: EDF

The partnership supports the cost reduction of a key low-carbon energy technology crucial to the UK’s future carbon-neutral economy in line with the Industrial Strategy and the Nuclear Sector Deal. The partnership provides EDF with an important module of their multi-physics digital twin. It also aligns and adds value to a number of national initiatives, including NVEC (Nuclear Virtual Engineering Capability) and the BEIS Nuclear Innovation Programme in which members of the partnership lead or participate.

The partnership will enable collaboration with the Small Modular Reactor Programme led by Rolls-Royce (through Jacobs and NNL) and the UKAEA’s STEP programme. Even with significant investment, there is a limit to how far current nuclear industry manual procedures can be developed to meet the demands of a carbon-neutral economy by 2050. Disruptive technologies, accepted by the regulator, are needed to accelerate construction and reduce the cost of operation. The digital framework which we will develop will be compliant with Gemini principles, to ensure its alignment with national digital initiatives such as National Digital Twin Programme of Digital Built Britain and Made Smarter.

Vision

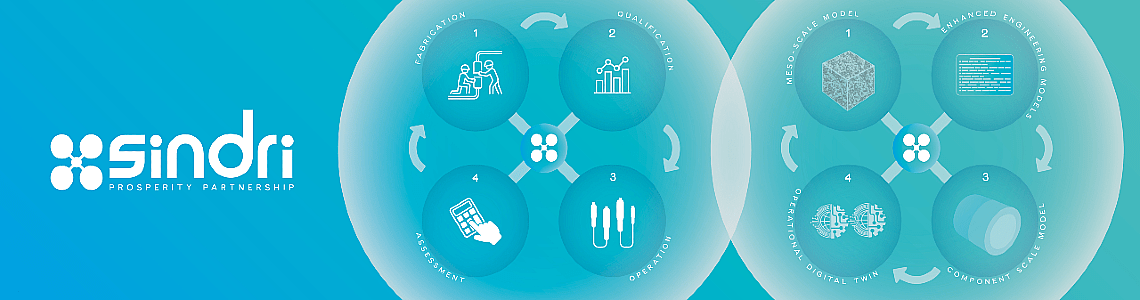

Our vision is to reduce the cost of nuclear power generation through an innovative change in the processes related to design, fabrication and life-time assessment. We will exploit the opportunity of digitally enabled materials to accelerate the implementation of novel designs, fabrication methods, and structural performance assessments.

So far these processes have been largely accomplished through manual iteration in the real-world environment, resulting in slow progress. This partnership will take advantage of new materials modelling frameworks and high-fidelity validation experiments to replace these processes with a virtual environment. We will use open-source, inter-connected, multi-physics, modular models instead, thus eliminating significant time-consuming and cumbersome human interventions.