For the past three months the Modelling and Simulation Centre at the University of Manchester has hosted three interns working on SINDRI projects and research.

In this Q&A, intern Cyrille Mignard tells us about his experience, the project he has been working on and how it will support his next career steps.

-

Why did you apply for this internship?

Whilst at the military academy of Saint-Cyr Coëtquidan, we have the opportunity during the first semester of our last academic year to go abroad for a three-month company internship.

I wanted to join an English-speaking country so I can improve my English. Well, the UK was the perfect choice as the birthplace of the English language. I was eager to discover the lands that inspired Shakespeare, and Robert Burns in Scotland!

-

What drives your interest in this subject area?

I am in the structure mechanic branch in the academy, and the microscale polycrystal subject area was a new subject for me in relation to what I have been working on in the Academy; it is this continuity that made me choose this subject.

Moreover, the EDF and SINDRI project have strong ambitions in support of the net-zero target – I was glad to join them in this endeavour.

-

What was the main focus of your internship?

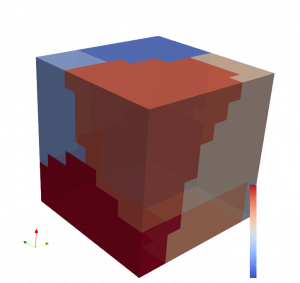

I focused on the validation process of a polycrystalline-plasticity law, developed by the University of Manchester and adapted by EDF for the code_aster software. This law is written with UMAT routine and adds in its formulation the size of the grains. It considers the impact of the morphology of the grains in a polycrystal; that is why it is called the length scale UMAT. This law is a step forward in the modelling of microscale polycrystal.

In partnership with the University of Bristol, I pushed this law throughout several simulations in code_aster, and they were benchmarked with Abaqus simulations with Dr Eralp Demir conducting the analysis in the University of Bristol.

-

What were the main results and outcomes of your work?

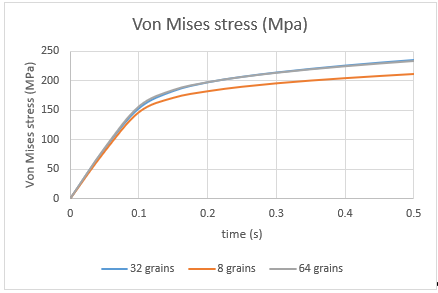

The simulations led to encouraging results for the usability of the law between code_aster and Abaqus. The UMAT is able to be run on very binding simulation like large deformation, high loading rate, and compression and tensile cyclic loading, with very close results in the benchmark studies. This was even more encouraging to see that code_aster models presented more robust results and faster results than the Abaqus models.

We are still encountering discrepancies with the quadratic meshes and this will have to be investigated further.

I was able to test the material behaviour on various models and was quite encouraged to see the numerical response of simulations on different samples with different sizes of grain. This emphasised the fact that the smaller the grains, the more resistant is the polycrystal, until it reaches a limit where the grains parameters (orientation, phase) don’t have an impact on the polycrystal.

-

How do you think this experience will support your future career plans and aspirations?

The method of work and research that I learned during this internship will remain a method that can be applied in all the type of mission I will do. Moreover, I also learned a lot about team working; in coordination with the EDF UK Centre team confronting the results between the different operators.

Improving my English will also be point that will support my future career plans. All lots of good things that I that could apply in my military career.

View another intern profile from Augustin Pourcel here.