For the past three months the Modelling and Simulation Centre at the University of Manchester has hosted three interns working on SINDRI projects and research.

In this Q&A, intern Augustin Pourcel tells us about his experience, the project he has been working on and how it will support his next career steps.

-

Why did you apply for this internship?

I am currently in master’s degree in mechanics and my course requires that I do a three-month internship in this field of studies. I chose to apply in EDF R&D UK for several reasons. First, it was the opportunity to discover the work in a R&D service, and experience teamwork. Then, it was the opportunity to travel to the United Kingdom, to practice English and to discover the culture of a neighbour of my own country, France. And finally, the proposed subject was exactly in the continuity of my learnings, so it was the occasion to make a concrete use of them, as well as learning new skills, like programming.

-

What was the main focus of your internship?

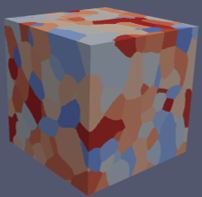

My internship focused on the automation of the EBSD-CPFE conversion process: the idea was to automate a process for generating Crystal Plasticity Finite Element (CPFE) models for the analysis of polycrystalline microstructures, by using the data given by Electron Backscatter Diffraction (EBSD).

This is a technique that gives information about the morphology of the microstructure, like the grain shapes, but also about the orientation of the grains composing the microstructure. This process should help to gain time and to avoid manipulation errors.

- What were the main results and outcomes of your work?

We were able to create a first version of a fully automated process, that is able to generate either a digital twin of a microstructure, or a cubic microstructure based on the data from an original microstructure. It is really encouraging, especially since the research team of the University of Bristol has already adopted it to perform their simulations.

Since the structure of the process is simple, it can be easily modified and improved by the different users. This makes it a very practical tool for further research.

-

How do you think this experience will support your future career plans and aspirations?

The most important takeaways are in human terms: it is always interesting to experience teamworking and to face complex issues, especially when it is related to a subject that requires to develop new skills. Besides, in terms of autonomy and organisation, this internship taught me a lot. It was also the first time I had to practice English in a scientific context, and it is certainly the best way to make progress.

View another intern profile from Cyrille Mignard here.